Demagnetisation

With the exception of heat treatment, it is important to remember that in order to effectively demagnetise a component the current used must be equal to or higher than that used whilst conducting the test, reversing in polarity and decreasing in strength.

Demagnetisation of a specimen may be required before testing, between successive shots/magnetising positions, and/or after testing in order to remove any residual magnetism in the specimen.

Demagnetisation may be carried out for the following reasons:

- To remove any residual magnetism which may remain from previous MT procedures or other sources, which may interfere with the subsequent test.

- To remove any residual magnetism between successive MT shots in the test procedure as this may interfere with the capability of the next successive shot (particularly when changing the direction of magnetisation).

- To remove any residual fields after MT has been carried out so as not to interfere with other work processes, e.g. a residual magnetic field may attract cutting swarf during machining operations and may also interfere with subsequent welding operations causing arc-blow. Arc blow is where the welder cannot control the arc resulting in large amounts of spatter and/or lack of fusion, as well as other possible weld defects). (Generally, a field = 40g is required if welding on dc prior to arc blow).

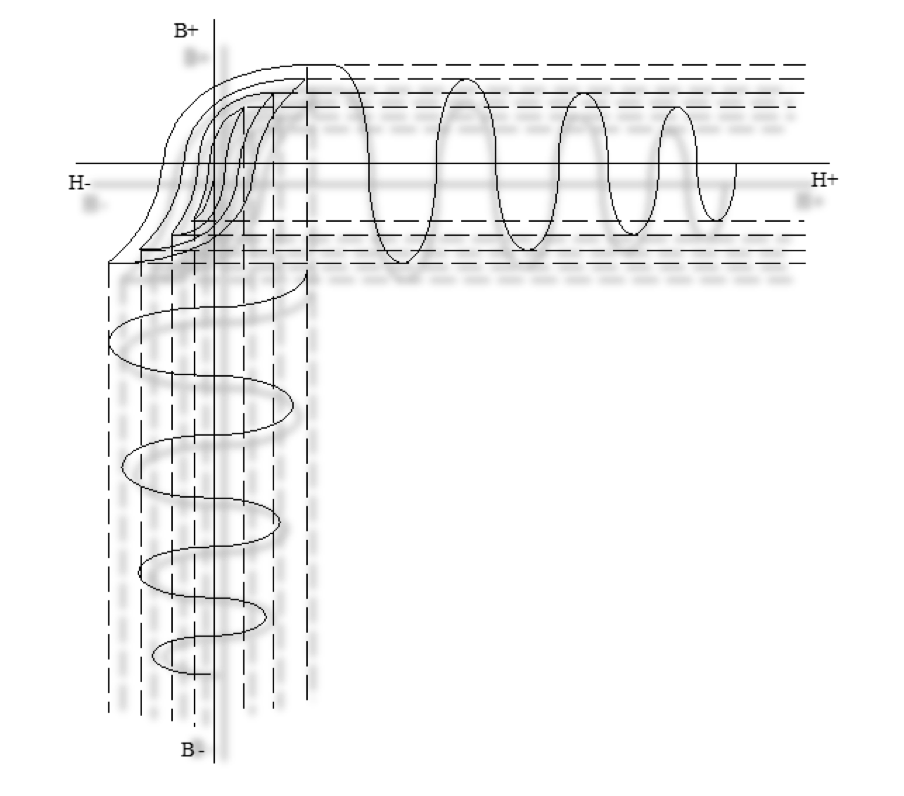

Fig. 7.1 Hysteresis loop showing demagnetisation.